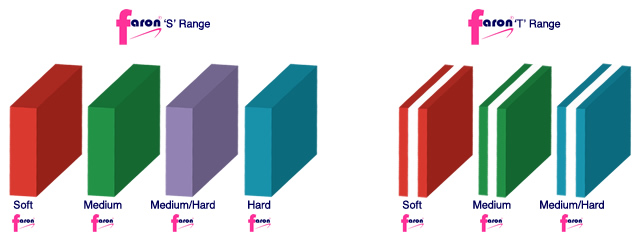

Faron S and Faron T Squeegee Blades Ranges

| Blade No. | Blade Type | Hardness Shore 'A' (+/-5) | Thickness mm (+/-0.3) | Width mm (+/-1) | Length mm (+/-5) | Profile | |

|---|---|---|---|---|---|---|---|

| Red Squeegee - 65 Shore A | |||||||

| SR525 | Single | 65 | 5 | 25 | 2650 | Square | |

| SR735 | Single | 65 | 7 | 35 | 2650 | Square | |

| SR950 | Single | 65 | 9 | 50 | 2650 | Square | |

| TR735 | Triple | 65 | 7 | 35 | 2650 | Square | |

| TR950 | Triple | 65 | 9 | 50 | 2650 | Square | |

| Green Squeegee - 75 Shore A | |||||||

| SG525 | Single | 75 | 5 | 25 | 2650 | Square | |

| SG735 | Single | 75 | 7 | 35 | 2650 | Square | |

| SG950 | Single | 75 | 9 | 50 | 2650 | Square | |

| TG735 | Triple | 75 | 7 | 35 | 2650 | Square | |

| TG950 | Triple | 75 | 9 | 50 | 2650 | Square | |

| Purple Squeegee - 80 Shore A | |||||||

| SP525 | Single | 80 | 5 | 25 | 2650 | Square | |

| SP735 | Single | 80 | 7 | 35 | 2650 | Square | |

| SP950 | Single | 80 | 9 | 50 | 2650 | Square | |

| Blue Squeegee - 85 Shore A | |||||||

| SB525 | Single | 85 | 5 | 25 | 2650 | Square | |

| SB735 | Single | 85 | 7 | 35 | 2650 | Square | |

| SB950 | Single | 85 | 9 | 50 | 2650 | Square | |

| TB950 | Triple | 85 | 9 | 50 | 2650 | Square | |

Call us now on 0113 3873102 for Pricing Details. Then when you are ready to place an order click HERE for our easy to use order form.

Call us now